Naturalpár’s grinding and milling services ensure that spices, seeds, herbs and other raw materials are processed to the desired particle size and texture. With our modern technologies, we produce uniform, high-quality grinds while preserving the nutritional value of the products.

Precise grinding technology to achieve the desired fineness.

Gentle processing that does not damage the product’s nutritional content.

Efficient processing even in industrial quantities.

Documented and controlled production process.

Different raw materials require different processing methods. Naturalpár uses several grinding technologies to ensure the best possible quality.

After the dried spice paprika passes through the hammer mill, it is ground between tightly set, horizontal pairs of stones. Between the millstones, the spice paprika warms up. As a result of the heating and grinding, the oil contained in the seeds extracts the colouring agents from the skin, which then coat the plant particles of the spice paprika. This process gives the ground paprika a more uniform and intense colour.

Stone grinding is followed by conditioning, where the moisture content of the grind is adjusted to the optimal 8–11% water content using purified, softened water with intensive mixing. At the end of stone grinding, the grind is sieved through a control sieve with a hole diameter of 0.5 mm.

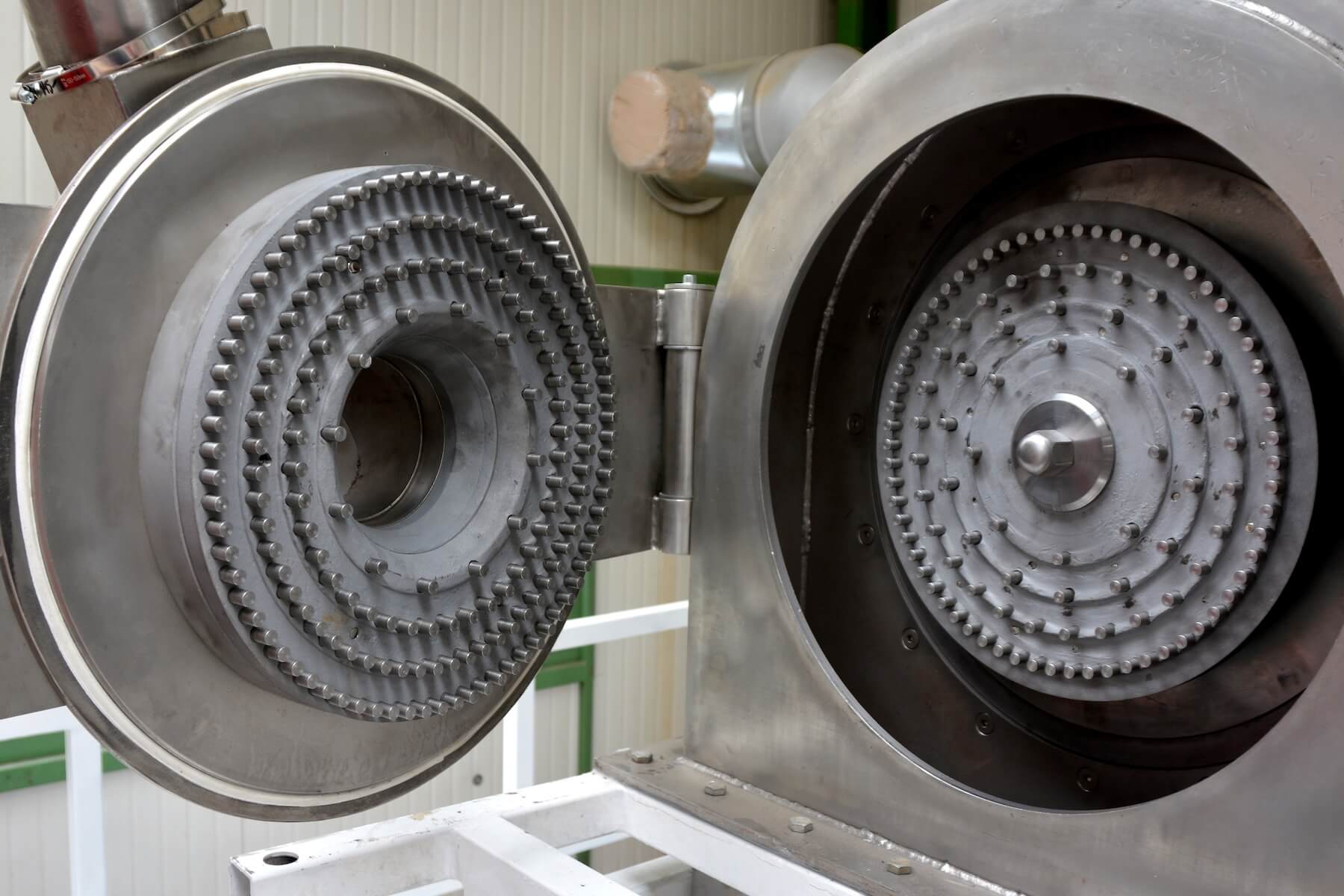

Grinding takes place between the stationary pin disc mounted on the openable door and the pins on the rotating rotor. The system is equipped with a conditioning unit and a control sieve, ensuring the appropriate particle size of the grind. Capacity: 200–1,000 kg/hour

Grinding and milling of various dried products (mushrooms, horseradish, etc.), spices (spice paprika, pepper, caraway, etc.), seeds (barley, malt, oat flakes, pressed products, etc.).

If you need professional grinding and milling solutions, contact us!

We will help you find the processing method that best suits your needs.

Request a quote now to ensure premium quality for your products!